Weed prevention and control at mega-solar power plants

Is DuPont™ Xavan® weed control fabric necessary for weed control at mega-solar power plants?

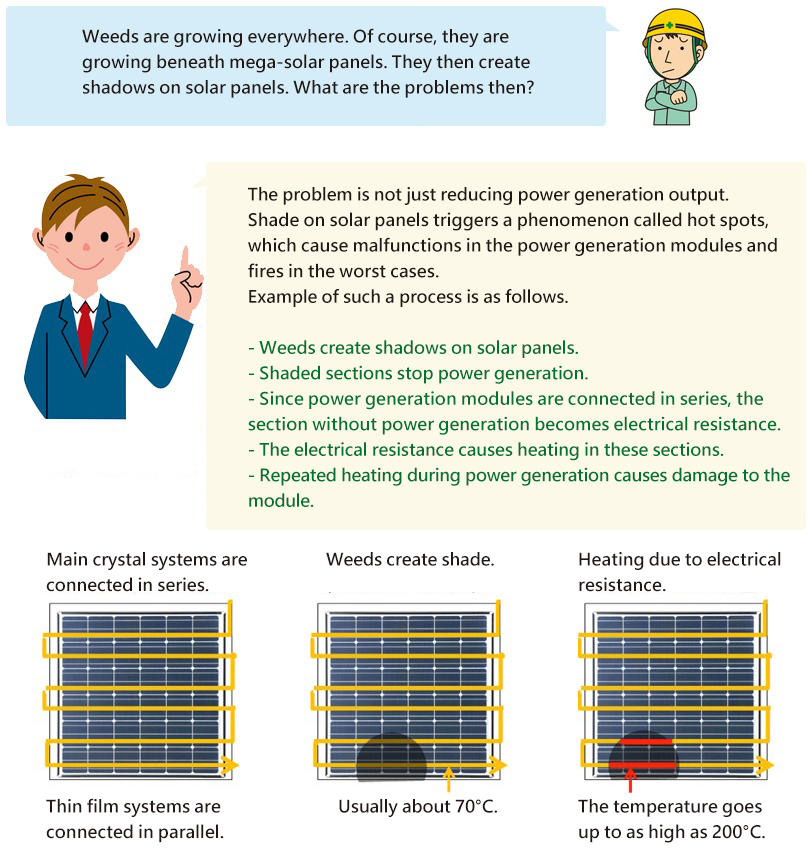

Since solar power generation is associated with the impression of maintenance-free, weed control is actually a huge trap.

Is there any other effective ways?

● Seed spraying

Intentionally grow plants, such as clover, to give advantages to them over other weeds. There is no concern of durability since plants are used. In addition, plants have the effect of cooling down the area. The initial cost is slightly high, and additional costs, such as the cost of watering, may be required. Sustainability and certainty of expected effects vary greatly.

● Spraying of herbicides

The initial cost is the lowest. Yet, regular spraying is required, and cost effectiveness, including running costs, needs to be considered. Prior assessment is required to check the effects on soil, human health, and facilities.

● Weed-proof soil

This method covers an area with weed-proof soil. The price range is broad, but mostly costly. Continuity and certainty of effects require examination. Vehicles cannot drive over the type with hardening surfaces, and plans must be created to repair cracks.

● Manual weeding

Regular employment is required. The safety of workers must be ensured because they work within a power plant and often under the blazing sun and summer heat. Workers must use mowers very carefully because pebbles shot from mowers may damage facilities.

● Covering with gravel

The initial cost is relatively low. A gravel covering can reduce weeds to some extent for some period. The gravel gradually mixes with the soil, and the effects become lower. The speed of mixing increases depending on the volume of pedestrian and vehicle traffic. Thus, regular refilling of gravel may be required. It is difficult to completely remove the gravel mixed with soil when the property needs to be returned as raw land.

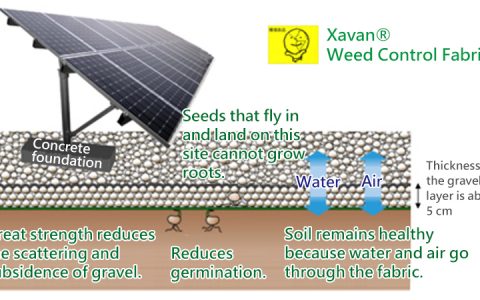

● Xavan® weed control fabric

The effect is ensured, and the cost is relatively low.

Since the fabric gradually deteriorates under direct sunlight, the surface needs to be covered with soil or gravel.

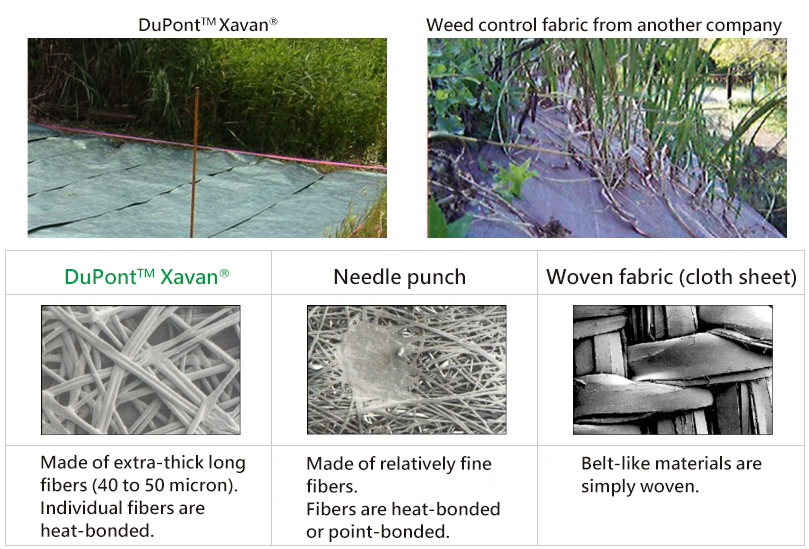

Are other fabrics not acceptable?

1. High resistance to penetration (= ensured weed control)

Weed growth cannot be controlled simply by blocking sunlight. No matter how perfectly the fabric blocks sunlight, plants conduct photosynthesis under the fabric once they penetrate through it.

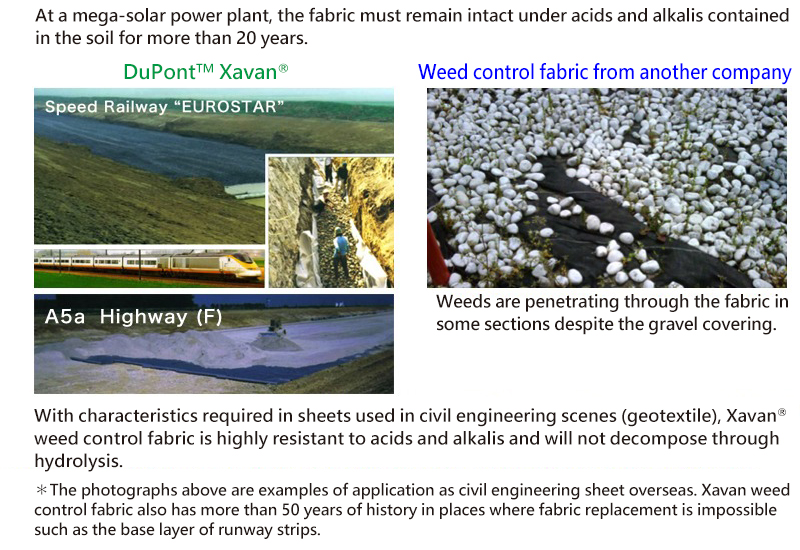

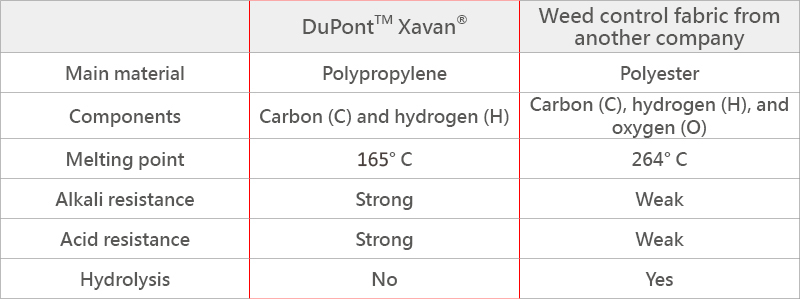

2. Durability over the years

This fabric is highly resistant to alkalis that leach out of crushed concrete gravel. Yet, crushed concrete gravel usually contains fine particles, and some weeds may start growing on a pebble layer that is as thin as about 5 cm. Prior assessment is recommended when using crushed concrete gravel.

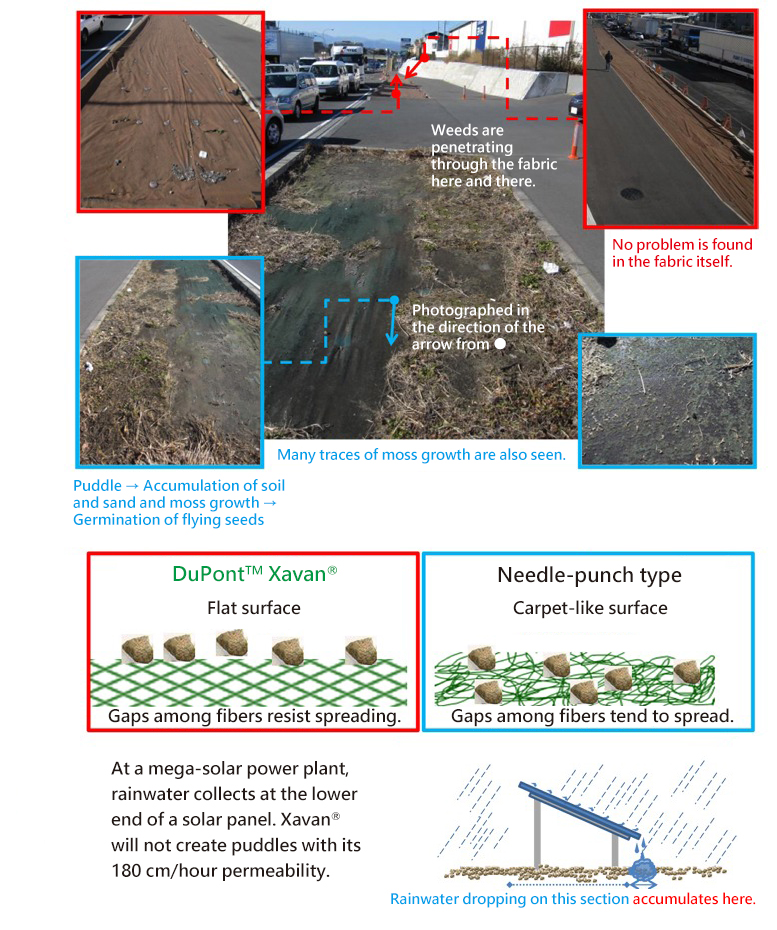

Long-lasting permeability

Xavan® weed control fabric is made by heat-bonding extra-thick fibers, and gaps among the fibers resist expansion, which makes this fabric a tough layer for weeds to penetrate.

Xavan® weed control fabric has a clog-resistant structure, and its permeability will last for a long time. It also reduces ill effects caused by puddles created on the fabric.

3. Easy installation

The fabric can be cut freely to fit the shape of frames. Since individual fibers are bonded, cut sections will not come loose. Since the fabric is light, people can easily handle it. Fatal damage to the fabric is not likely to occur even when it is run over by heavy machinery or gravel is dropped onto it.

Lightweight: 240 G 1 m × 30 m weighs about 7.2 kg.

Easy to cut

Pinholes will not be likely to expand.

Damage resistant

Separation effect

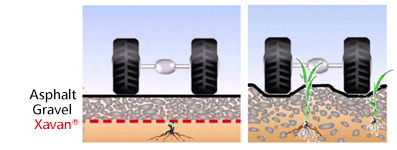

Thanks to its high tensile strength, the subsidence of gravel can be reduced compared to a case with a gravel layer only. Therefore, the formation of ruts caused by vehicle traffic can be reduced. It is also easy to remove gravel upon removal.

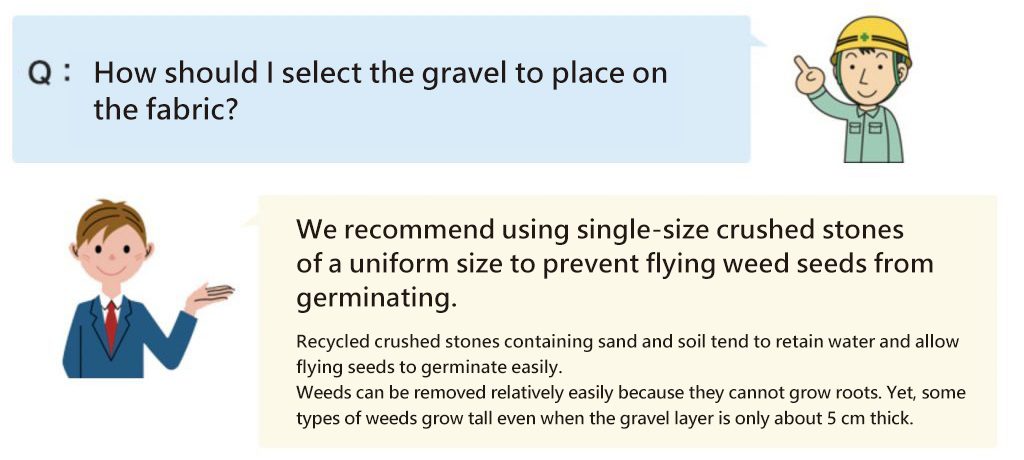

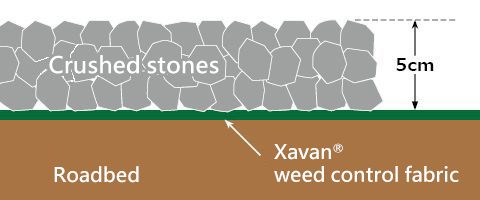

Recommended size: Crushed stone with a single size of 5

Thickness: About 5 cm on average

*Weeds germinate quickly if the gravel layer is too thick.

←○ Ideal Crushed stone with a single size of 5

*The size is mostly uniform, and soil or sand is not mixed in the gaps.

←× Not appropriate Recycled crushed stone

*Mixed with a large amount of soil and sand, which easily allows weed germination.

■Plastic pin

Pins to secure the fabric when a gravel layer is created on the top

Example of installation (Chiba)

1. Immediately after installation

2. Four months after installation

3. One year after installation

Fabric deterioration caused by UV rays is reduced, and durability has increased.

Maintenance after installation can be reduced if tools to secure the fabric are used.

*The following are the instructions for securing the fabric in place without covering.

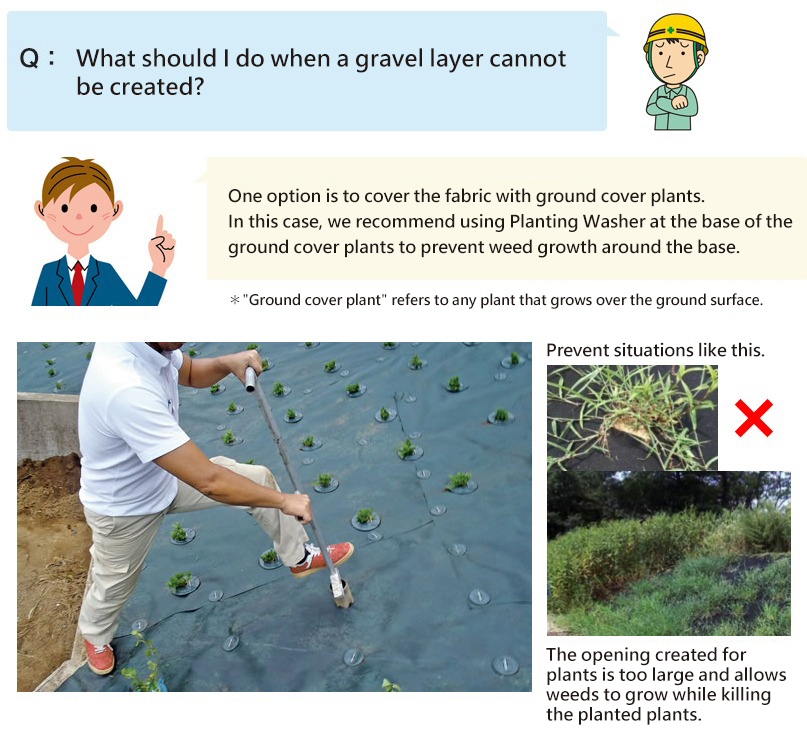

Weed Control Washer®

Prevents weed growth through pinholes and flattening of the fabric.

U-shaped pin

Connecting tape

For taping edges and repairing the holes created by wrong pinning

× Weed Control Washer to control weeds growing through the pinholes

× Connecting tape to control weeds growing through accidentally created holes

Example of exposed installation

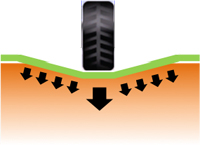

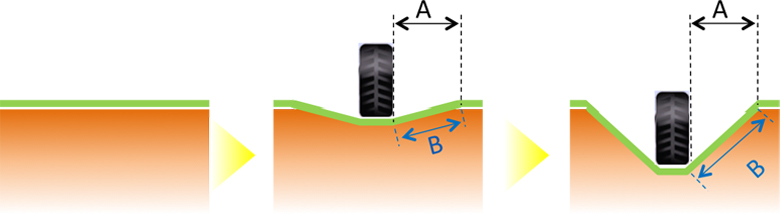

The heavy machinery will sink if it drives over soft ground.

With Xavan®, the weight of the heavy machinery is distributed to the nearby ground.

In this step, Xavan®

1. Starts sinking into the ground.

2. If the fabric is secured,

- the fabric near the secured section will stretch.

- the fabric near the tires of the heavy machinery stretches.

3. If sinking reaches above the coefficient of extension (240 G: 55%), the fabric will rupture.

With Xavan®, the weight of the heavy machinery is distributed to the nearby ground.

In an extreme example,

B/A1.55 → Rupture

*Some difference actually occurs depending on various factors, such as soil bearing capacity, viscosity of soil, speed of weight application, contact area with tires, friction coefficient of the ground, weight, contact area, and friction coefficient of gravel covering, and fabric securing method. Having said that, the pins usually fall off first under ordinary conditions.

Q: Don’t weeds grow from the gravel?

Some weeds start growing when low-grade gravel is used because they contain fine particles. Yet, since their roots cannot penetrate through the fabric, they are not likely to grow tall. If the gravel layer is too thick, soil and dust accumulate in the gravel, and weeds may start growing in some cases.

Q: If the soil is stirred deeply during ground preparation, I suppose seeds will sink deep into the ground and will not germinate.

Many seeds that are buried deep in the ground will not germinate. Yet, seeds blowing in the wind will start growing without the fabric. Even if there is fabric, seeds will start growing if the fabric yields to the penetration force of the seeds.

Q: I suppose the soil bearing capacity will decrease with water that permeates through the fabric.

The soil bearing capacity will not decrease compared to a case without the fabric (= when the soil bearing capacity is measured). Meanwhile, since the moisture content in the soil is related to the soil bearing capacity, Xavan® is not suitable for cases such as a plan to improve soil bearing capacity by covering the ground surface with a non-permeable sheet to lower soil moisture through a detailed water draining plan and operation.

This content does not support the efficacy or feasibility of the above plan.

Q: I suppose fabric is not necessary under solar panels.

Fabric may become unnecessary by implementing other methods to fill spaces among modules.

Still, we recommend installing fabric in front of solar panels as shown on the right.

Q: Does it contain any substance that would affect the environment?

No. Factories certified for ISO 14000 ship products that comply with RoHS and REACH.